01 應(yīng)用背景

起重機(jī)作為工業(yè)生產(chǎn)中不可或缺的重要機(jī)械設(shè)備,承擔(dān)起吊、搬運(yùn)和安裝等重任,但限于實(shí)際使用環(huán)境的復(fù)雜性和漫長的使用周期,往往因各種因素降低了設(shè)備的安全性和可靠性,極端情況下可能導(dǎo)致嚴(yán)重的安全事故,對(duì)設(shè)備本身及作業(yè)人員安全構(gòu)成巨大威脅,并造成重大的經(jīng)濟(jì)損失。具體而言,起重機(jī)常見的故障問題包括電氣系統(tǒng)問題、機(jī)械部件損壞、載重超負(fù)荷以及因忽視定期維護(hù)和保養(yǎng)而導(dǎo)致的設(shè)備性能衰退和老化。

針對(duì)以上問題,亟需針對(duì)該設(shè)備特點(diǎn)研發(fā)一套機(jī)械設(shè)備的狀態(tài)監(jiān)測(cè)與安全性評(píng)估系統(tǒng),以便實(shí)時(shí)監(jiān)測(cè)起重機(jī)的運(yùn)行狀態(tài),增強(qiáng)設(shè)備運(yùn)行的安全性與可靠性。

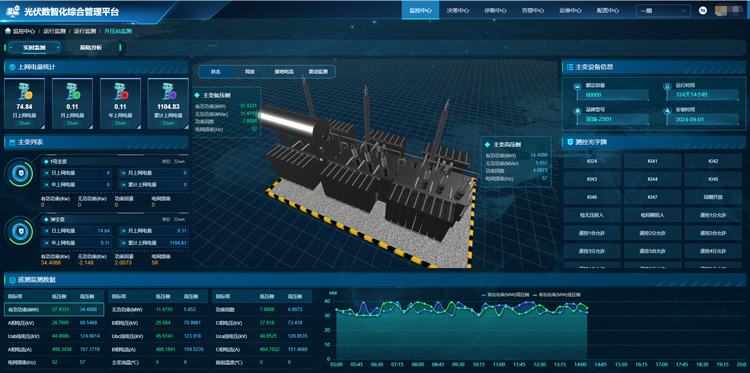

02 應(yīng)用方案

本方案依托溫振復(fù)合傳感器VBL30的簡易部署優(yōu)勢(shì),通過在行車走行部軸承端蓋上安裝溫振復(fù)合傳感器,牽引電機(jī)上安裝轉(zhuǎn)速傳感器,采集走行部軸承的振動(dòng)/溫度數(shù)據(jù)和牽引電機(jī)的轉(zhuǎn)速數(shù)據(jù),通過4G傳輸?shù)皆贫朔?wù)器,最終利用系統(tǒng)搭載的自主智能診斷模塊對(duì)軸承數(shù)據(jù)進(jìn)行診斷分析和健康管理。現(xiàn)場(chǎng)安裝方案如圖2-1所示。

圖2-1 監(jiān)測(cè)方案示意

圖2-2 硬件參數(shù)、特點(diǎn)介紹

03 自診斷預(yù)警

2024年4~5月,行車軸承在線監(jiān)測(cè)和健康管理系統(tǒng)陸續(xù)上報(bào)告警信息,提示A行車區(qū)域的6#、8#測(cè)點(diǎn)監(jiān)測(cè)對(duì)應(yīng)的軸承狀態(tài)存在異常,報(bào)警類型為:振動(dòng)特征參量異常。溫振傳感器測(cè)點(diǎn)位置如圖3-1所示,健康管理系統(tǒng)也給出了報(bào)警結(jié)論,見圖3-2。

圖3-1 設(shè)備概況與測(cè)試布置示意

圖3-2 自診斷結(jié)果界面

04 分析師復(fù)核

4.1 6#測(cè)點(diǎn)數(shù)據(jù)分析

如圖4-1(a)和圖4-1(b)所示分別為6#測(cè)點(diǎn)在4月6日和5月11日的振動(dòng)加速度信號(hào)頻域結(jié)果。由圖可知,6#測(cè)點(diǎn)軸承振動(dòng)信號(hào)的加速度頻譜圖上始終存在頻率約為450Hz的1倍、2倍(約為900Hz)諧頻的能量簇。根據(jù)以往經(jīng)驗(yàn)并結(jié)合特征值趨勢(shì)可知,該測(cè)點(diǎn)疑似存在磨損缺陷,結(jié)合圖2特征值趨勢(shì)可知,5月11日的特征值幅值相較于4月6日明顯增大,且出現(xiàn):異常特征值頻次增多、異常值呈現(xiàn)高度聚類特性,建議進(jìn)行重點(diǎn)檢查。

(a)4月6日

(b)5月11日

圖4-1 6#測(cè)點(diǎn)信號(hào)的頻域結(jié)果

(a)4月6日

(b)5月11日

圖4-2 6#測(cè)點(diǎn)信號(hào)的振動(dòng)特征值變化趨勢(shì)

4.2 8#測(cè)點(diǎn)數(shù)據(jù)分析

如圖4-3所示為8#測(cè)點(diǎn)在4月6日的振動(dòng)加速度信號(hào)頻域結(jié)果。由圖可知,與6#測(cè)點(diǎn)類似、8#測(cè)點(diǎn)軸承振動(dòng)信號(hào)的加速度頻譜上存在頻率f約為453.6Hz、600Hz以及905Hz的能量集簇。根據(jù)以往經(jīng)驗(yàn)并結(jié)合特征值趨勢(shì)可知,該測(cè)點(diǎn)疑似存在磨損缺陷,但相較于6#測(cè)點(diǎn)、缺陷的劣化程度較小,但同樣建議進(jìn)行維護(hù)。

圖4-3 4月6日 8#測(cè)點(diǎn)信號(hào)的頻域結(jié)果

05 檢修驗(yàn)證

如圖5-1(a)所示,經(jīng)運(yùn)維人員拆卸檢修后發(fā)現(xiàn)6#測(cè)點(diǎn)軸承存在內(nèi)圈故障,內(nèi)圈出現(xiàn)磨損及損傷、導(dǎo)致邊緣部分出現(xiàn)翻卷。若未得到及時(shí)處理,該故障會(huì)進(jìn)一步導(dǎo)致軸承完全失效,甚至引起更嚴(yán)重的設(shè)備故障。如圖5-1(b)所示為8#測(cè)點(diǎn)軸承的現(xiàn)場(chǎng)拆解示意,由圖可知,該軸承同樣出現(xiàn)了異常,軸承表面存在磨損且在外圈部分發(fā)現(xiàn)鐵屑,若未得到及時(shí)處理,該缺陷會(huì)持續(xù)影響軸承的潤滑狀態(tài),進(jìn)一步加劇磨損。

(a)6#測(cè)點(diǎn)對(duì)應(yīng)軸承

(b)8#測(cè)點(diǎn)對(duì)應(yīng)軸承

圖5-1 6#和8#測(cè)點(diǎn)軸承現(xiàn)場(chǎng)拆解情況

06 客戶價(jià)值

基于本方案針對(duì)行車軸承進(jìn)行實(shí)時(shí)狀態(tài)監(jiān)測(cè),可實(shí)現(xiàn)被檢測(cè)設(shè)備早期缺陷的有效預(yù)警與劣化程度的精準(zhǔn)感知,進(jìn)而構(gòu)筑被監(jiān)測(cè)對(duì)象完整的設(shè)備健康度評(píng)價(jià)體系。

-

監(jiān)測(cè)

+關(guān)注

關(guān)注

2文章

3654瀏覽量

44743 -

機(jī)械設(shè)備

+關(guān)注

關(guān)注

0文章

353瀏覽量

18797 -

系統(tǒng)

+關(guān)注

關(guān)注

1文章

1019瀏覽量

21427

發(fā)布評(píng)論請(qǐng)先 登錄

相關(guān)推薦

電纜護(hù)層環(huán)流在線監(jiān)測(cè)裝置|為電力系統(tǒng)的運(yùn)維管理提供有力支持

工業(yè)設(shè)備健康運(yùn)維管理平臺(tái)是什么

捷杰傳感助力某礦業(yè)集團(tuán)球磨機(jī)智能運(yùn)維

基于電力智能網(wǎng)關(guān)的充電樁在線監(jiān)測(cè)方案

設(shè)備運(yùn)維管理IoT云平臺(tái)的應(yīng)用價(jià)值

設(shè)備運(yùn)維管理平臺(tái)的組成及功能

電力監(jiān)測(cè)智能運(yùn)維管理系統(tǒng)解決方案

光伏電站運(yùn)維管理系統(tǒng):智能化時(shí)代的高效解決方案

裝船機(jī)數(shù)據(jù)采集在線運(yùn)維物聯(lián)網(wǎng)系統(tǒng)

港口起重機(jī)遠(yuǎn)程監(jiān)控運(yùn)維管理系統(tǒng)解決方案

制氫機(jī)遠(yuǎn)程監(jiān)控運(yùn)維方案

實(shí)施案例丨捷杰傳感在線監(jiān)測(cè)和健康管理方案助力港口行車高效運(yùn)維

實(shí)施案例丨捷杰傳感在線監(jiān)測(cè)和健康管理方案助力港口行車高效運(yùn)維

評(píng)論